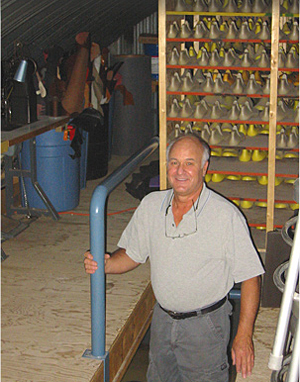

Randy Merrell in his Utah footlab. (all photos reprinted courtesy of Merrell)

Randy Merrell remembers his father's reaction in 1974 when the young man, recently returned from a mission to Brazil and soon to be married, announced he wanted to earn his living by making boots.

“That's the stupidest idea I ever heard of in my life. A man can't provide for a family with the work of his hands,” Merrell remembers being told. And that settled it. “So of course it was set in stone that I had to do it.”

Today, Merrell's name is known throughout the outdoor world thanks to the Merrell Boot Company, the business he created with John Schweitzer and Clark Matis in 1981. He and the company parted ways amicably, five years later, but it still carries his name.

As for Merrell, he's still making custom leather boots by hand and has become an expert pedorthist, creating custom orthotics for people who don't want foot problems to keep them out of the wilderness.

Merrell loves a challenge. In fact, it was the challenges his own father set him to solve on the family's horse ranch near Vernal, in northeastern Utah, that gave him the experience and confidence to say today, “I can do anything and fix anything.”

As a boy that meant building fences and barns, shoeing horses, mucking stalls, hauling hay, delivering foals, and repairing the pump. What Merrell fixes today in his Merrell FootLab workshop in remote Vernal is people's feet. More specifically, he figures out what makes a person's feet hurt so much when they try to pursue their favorite activities. Then he designs custom orthotics or footwear to solve those problems and get his clients back to work or back on the trail.

Merrell works on a boot, circa 1980.

Merrell's formal education in bootmaking began at the Lynn Independent Industrial Shoemaking School, in Lynn, Mass. At Lynn, he learned shoe and bootmaking and last and pattern making. His stay there in 1975 was “the coldest winter ever,” he said. It must have been cold indeed to impress a young man who remembers lows of 35 below zero Fahrenheit during his childhood in northern Utah.

After completing the Lynn program, Merrell brought four sewing machines home with him on the train, along with some leather and thread, and bought some lasts and the contents of a retiring Salt Lake shoe repairman's business. He took up shop in a garage on his father's Utah ranch and with his wife, Lou-Ann, helping alongside, Merrell started designing and making Western style cowboy boots.

Merrell continued his formal education a couple years later at Oklahoma State Technical College in Okmulgee, Okla., where he learned custom Western bootmaking from Earl Bain. “Earl was a Western bootmaker,” said Merrell reminiscently. “He had no idea about patterns or fittings or orthotics, but he was a great bootmaker.”

Merrell first perfected his craft on cowboy boots, but the avid backpacker eventually turned his attention to hiking boots. Most of the hiking and backpacking boots then sold in the United States came from Europe and were heavy, stiff, and fit for a European foot. Merrell set out to make a lighter weight, more flexible version based on the fit of his cowboy boots: a roomy toebox, precise instep, and snug heel.

The result was the M1—the Model 1—designed to fit North American feet and take on North American mountains and canyons. “It's the kind of boot I still make for ninety percent of my clients,” said Merrell.

Custom hikers with a Norwegian Welt construction

Merrell continued to perfect the M1 and was wondering how to break into the hiking boot market when he saw an article in Backpacker magazine inviting readers to join a strenuous Grand Canyon outing. Merrell wrote in and was chosen to join 11 other people, including the magazine's founding editor, Bill Kemsley, on the trip. (Merrell still wonders how he came up with the required $650.)

He ended up taking boot orders from three members of the trip, including Kemsley, and Backpacker included some of his information on boot care in its companion newsletter, Footnotes.

Soon after, Backpacker needed a boot article after the one scheduled fell through. Merrell agreed to write a piece on hiking boot construction and fit, and “Trade Secrets of the Bootmaster” appeared in the April-May 1981 issue (you can read it online through a Google Books title search). After Backpacker named Merrell's $500 custom hiking boots the most comfortable and functional boots in North America, the waiting list for a pair grew six months long.

“All of a sudden I was a celebrity,” said Merrell.

At the same time, Clark Matis and John Schweitzer, former Rossignol employees, wanted to start their own hiking boot company. The pair previously had approached custom bootmaker Limmer Boots, but were turned down. After seeing Merrell's Backpacker article, Matis and Schweitzer approached the cowboy-hiking bootmaster with their idea. Merrell agreed and the Merrell Boot Company, with the M1 as its foundation, was born in 1981 in Waitsfield, Vt.

His five years with the company that bears his name were “enormously instructive,” said Merrell. He was able to work with bootmakers and pattern makers in Europe whose trade heritage went back several generations. “I went to Europe and met bootmakers there, like Alfons Meindl (in Bavaria). He became something of a father to me.”

Merrell cuts a pair of hiking boot uppers.

Another trip during that period took him to Intervale, N.H. “Limmer Boots in New Hampshire is the gold standard for custom outdoor boots in the U.S.,” he said. “A Bavarian (Peter Limmer Sr.) settled there. I met his son Francis and spent a delightful day with him.”

But the corporate world wasn't for Merrell, and after five years he left the company behind and went back to being his own boss, cutting leather by hand and meeting clients' needs one-on-one. Asked if the Merrell Footwear company follows his ideals, he said, “No, I believe in leather. That said, I so much applaud what they do. They've been enormously successful building a good shoe.”

In fact, while the company has expanded its offerings widely, Merrell's Wilderness backpacking boot, introduced in 1983, is still on the footwear giant's roster more than a quarter century later.

Merrell returned to his craft on a smaller scale without regrets. For years, he turned out one or two pairs a week, “anywhere from forty to one hundred and ten in a year,” he estimated. Many of his customers came to him with special problems that needed more than just a pair of boots to solve. So in 1998, he decided to specialize in custom orthotics.

After more than three decades in business, Merrell acknowledges that his father was right about one thing: “It is hard to make enough money to support a family on the work of your hands.” And with Americans accustomed to buying inexpensive footwear made overseas, Merrell found the wages from spending four to ten days making one pair of custom footwear were just too low. “I also became passionate about dealing with faulty biomechanics of feet,” he said.

Merrell has 2,000 pairs of lasts on shelves in his footlab, another 8,000 are kept in storage.

Today, what started as Merrell Custom Boots is now Merrell FootLab whose mission is to help people whose feet have become or are becoming a limitation in their lives. That may mean custom orthotics, alterations to footwear, or custom boots.

Merrell sees himself as a problem solver. “I can help many more people than I did building custom footwear. These are people who have had trauma or congenital ailments or similar issues. A huge number of people are dealing with foot pain.”

Merrell's informal education has never stopped. He became a certified pedorthist and learned the craft of custom last making. He has eagerly learned from other bootmakers, and discovered that when he taught a class, at his home or at gatherings of other custom boot crafters and shoemakers, he would learn from his students' queries.

About twice a year, aspiring bootmakers can learn the craft directly from Randy Merrell and his instructors at the intensive Merrell Institute of Bootmaking. Over two weeks, participants learn the skills—pattern making, cutting skiving, stitching, lasting—to make at least two pairs of boots, a pair of hikers and either a pair of Western style or packer boots. Naturally, students also get an introduction to foot biomechanics.

“Twenty-five years of teaching two-week courses here at the shop have taught me a lot,” Merrell said. “Hundreds of students asking hard questions … now they're easier to answer.”

Besides helping customers and being his own boss, Merrell obviously loves to work with his hands. He remembers several artisan bootmakers he met in Brazil, and speaks of their work with admiration. He still owns a pair of boots he bought from a man in Sao Paulo state in the early 1970s: “Pedro did wonderful work with very little equipment.”

That Merrell also does wonderful work is evident from testimonials by clients. “He kept me walking,” was Bradford Oliver's summation of the experience. Oliver, a former nuclear submarine engineer turned executive recruiter, didn't want to stop hiking and hunting just because of major problems with his different-sized feet, including tendon issues and severe pronation. Other custom bootmakers failed to find a solution. But then he heard about Merrell from a store clerk in Minneapolis.

Custom backcountry telemark boots

Oliver, who now lives in Southern California, incorporated a visit to Merrell FootLab into a Utah hunting trip (Merrell requires clients visit him in-person for a proper diagnosis and fit). Merrell sized up not just his feet, but also his lifestyle and the way his particular foot problems affected the rest of his body. Oliver didn't just stand in the foam that orthotics makers use, he walked through it.

“Then it was sort of like a cook seasoning food,” Oliver said. “He made orthotics based on how my foot moves when I walk. He figured out the leg length difference and adjusted for how my foot pronates.” After three days of trying them out, Oliver returned for adjustments to the orthotics and to pick up a new set of boots. “The boots fit the first time,” Oliver said enthusiastically. “I have never had blisters in those boots.”

As an engineer, Oliver appreciates Merrell's approach to feet in their static and dynamic roles. And as a person, he appreciates Merrell's friendliness and commitment to helping. The little town of Vernal is remote, he acknowledged, “but there is no distance too great that would keep me from seeing him.”

Merrell hiking out of the Grand Canyon in 2003, wearing his own custom boots with orthotics.

Like many small towns in the Great Basin, Vernal is surrounded by lots of scenery and public land, perfect for outdoors enthusiasts but a bit off the beaten track for customers of a specialized service like Merrell's. He and his wife, Lou-Ann, who helps run the business and also acts as assistant bootmaker, could have a much bigger operation if they relocated to Salt Lake City or Provo.

But it's to the small town, with its dinosaur museum and its historic Latter-day Saints temple, that customers must travel. “Living in the city is not for me,” Merrell said. “And money has never been the goal.”

In fact, Merrell has found a silver lining in the economic downturn: “I'm grateful that things are a little more lax now.” He gets plenty of clients from all over the country, and he has no interest in returning to a time when he had a four-year backlog of boot orders. “The goal for Lou-Ann and me is to run our own business — not to let our business run us.”

Merrell remains a devoted backpacker. Now 59, he has gone backpacking in the Grand Canyon for 32 years, and has taken his wife and four sons into the canyon too. The boots he's made for himself enable him to keep it up, and his hobby enabled him to improve his designs.

“Here's a perfect example,” he said. “When I started in this business, boots were lined with leather into the heel area and a hole about the size of a twenty-five-cent or fifty-cent piece would wear in the heel lining. It's non-reparable. So I don't use lining leather there — I use heavy leather which won't wear.”

Merrell intends to spend many more years making feet happy: “I love my work. I have no intention of retiring.”

by Barbara Egbert

by Barbara Egbert