Survey your outdoor gear stash: your favorite base layers, comfiest fleece, go-to backpack. What’s it all made of? Where did it come from? What's the impact on the environment from your tools for outdoor adventures?

Being a sustainable shopper in the era of airline shipping and overseas outsourcing presents a slew of complicated scenarios: buy the backpack manufactured close by but that was made using harmful chemicals? Buy the recycled one and have it shipped thousands of miles to you? What if it’s non-recyclable and is going to end up in a landfill somewhere — does that trump all?

Answers to such eco-conscious conundrums are in the works.

For the past four years, the Outdoor Industry Association (OIA) has been working to develop the Eco Index — an evaluation tool for clothing, footwear, and outdoor gear that will assesses an item’s overall environmental impact, give companies a clear picture of their environmental footprint, and help them make decisions and changes to continue moving toward sustainable production.

The Eco Index was supported and developed initially by members of the outdoor retail and manufacturing industry, but in March, OIA announced a partnership with the Sustainable Apparel Coalition, which includes big-name companies like Target, Nike, Adidas, and Walmart. This means an even bigger push for the development of the Eco Index and a broader overall commitment to sustainable production.

Eco Index Origin

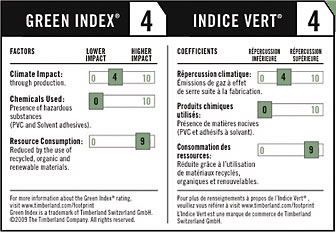

The idea for an industry-wide system for assessing environmental impact was hatched in 2007, according to Beth Jensen, corporate responsibility manager for OIA. While some companies like GoLite, Timberland, and Patagonia were already working to develop sustainable manufacturing practices and ratings, no set standards for sustainability assessment existed.

|

|

|

GoLite Index product score card

|

Timberland Green Index footwear rating

|

OIA formed the Eco Working Group, which today consists of more than 100 companies working to establish environmental guidelines by which to measure outdoor gear production. Phase One of the index was released in July of 2010. More than 100 companies, both in and out of the outdoor industry, are now participating in the pilot program. To ensure the index is a global effort, the European Outdoor Group’s Sustainability Working Group is a partner in the project.

“The point of the Eco Index, at least for now, was to enable companies to start speaking the same language to manufacturers and the supply chain and give tools to the product development team to step-by-step analyze the product they’re designing and reduce impact from the design phase forward,” said Kim Coupounas, chief sustainability officer for GoLite, a company that has been involved with the Eco Index project since its inception.

How it Works

Assessing the environmental impact and sustainability of thousands of products and trying to build a sensible, accurate system to measure and rate them all is — not surprisingly — highly complicated.

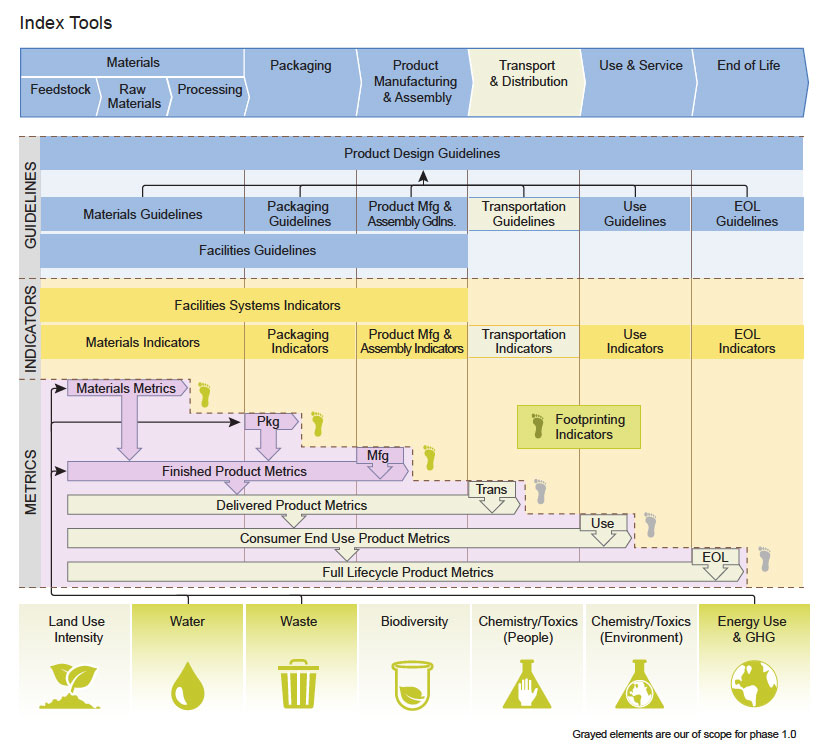

There are two major components the index takes into account:

- Life cycle stages of a product: materials; packaging; manufacturing and assembly; transport and distribution; use and service; and end of life.

- “Lenses” of impact: land use, water, waste, biodiversity, toxins (people and environment), and energy use/greenhouse gas emissions.

The Eco Index Tools.

The actual system, at present, is a series of documents and spreadsheets that are available on the Eco Index website. There are three tiers for evaluation: guidelines, indicators, and metrics, with each tier referencing specifics related to the life cycle stages and lenses of impact.

Confusing indeed, but the good news is, companies can approach the index piece by piece.

“The content is designed to be modular,” Jensen said, “so you can start with the guidelines, read through the best practices, and start to get your arms around what some things are that you could be doing or considering.”

The guidelines include basic suggestions like designing products with rechargeable energy sources that can be cleaned in cold water or don’t require dry cleaning, selecting materials that have a low carbon footprint, avoiding laminate and minimizing packaging, or making things recyclable.

The indicators level gets more technical, incorporating a point system for specifics within each life cycle stage. For example: Indicator #1 in the materials category is “percentage by weight of recycled content of a material.” A total of eight points are possible, depending on the percentage of pre- and post-consumer recycled material used to make an item and whether that material is certified as recycled by a third party.

Finally, in the metrics stage, Excel files are used to crunch numbers and make sense of the data you’ve generated in the indicator phase. Currently, there is no final “magic” number generated at the end of the process; a standardized rating system is still in development.

“Once these tools are robust and they’re in wide usage, we’ll have scoring,” Coupounas said, “but the first step is to get on the same page. What does it matter if a company says I have X score on an index if they don’t even really know how to reduce their environmental impact?”

Owen Hammond, director of operations and sustainability at Teko during the beta phase of the Eco Index, said that though the company already had a strong handle on basic sustainable practices, particularly on the materials side of things, the index helped them examine some aspects of sustainable practice they hadn’t yet considered.

“It did bring to light more on the facility side — what questions should we really be asking our factories?” he said. He also stated that for those companies just beginning to explore environmentally-friendly manufacturing, the index doesn’t have to be overwhelming or complicated. “You can use it one piece at a time, and it’s very possible to say ‘we’re just going to focus on materials and see how that comes out.’”

Internal vs. External Knowledge

As a consumer, you’re probably hoping for some handy website where you can plug in product info and come up with some number, some assurance that the jacket or backpack you’re choosing really was manufactured in an environmentally responsible manner.

No such luck — yet. Currently, the Eco Index is an internal measurement tool only, still in process, still being developed, changed, added to, and refined.

“Many companies are pushing for [publicizing the ratings] but as you get into this, you can see the complexity,” Jensen said. “It’s going to be a while before that happens.”

And at this stage in the game, both Jensen and Coupounas say the point isn’t to generate a number and rush to advertise how green their companies are anyway. They first must establish a clear, accurate system of communication and evaluation in the manufacturing industry as a whole. “We started with the basics — get our own house in order first,” Coupounas said.

Where the Index Stands

While OIA’s Eco Working Group has focused on developing content, the new partnership with the Apparel Coalition will bring the sustainable perspective to larger brands and retailers, according to Jensen. “The companies in the Sustainable Apparel Coalition cover about sixty percent of the global supply chain,” she said, “so they have the scale in the supply chain to be the tipping point.”

Jensen also anticipates the coalition having resources to put toward the development of an easy to use, more accessible software tool, which will be a massive project in and of itself. Meanwhile the Eco Working Group will continue developing content.

Committees are currently evaluating feedback from Phase One testing, Jensen said, and a footwear-specific tool is in the works, along with a gear-specific application for items like tents, backpacks, bicycles, and water and climbing sport items.

The Bottom Line

While developing a cohesive product sustainability measurement tool is an immense task, there are dedicated manufacturing companies making great strides in the right direction, and many companies are already committed to making the right choices not only for business, but also for the Earth and its natural resources.

Any environmentally conscious consumer would appreciate having some final, definite measurement verified by research — and it’s in the works. It’s going to take time and effort on behalf of manufacturers who care enough to invest the time, and plenty of consumer patience.

For now, take note of the companies involved in the Eco Working Group and know they’re paying attention to where their materials come from and how they can produce top-notch products that have less impact on the environment.

More Information

Eco Index Examples

There currently are no straightforward examples available of products impacted by using the Eco Index, given it is still developing. However, consider the following, from OIA and The Wall Street Journal:

- In redesigning its Jam Pack backpack (at right), GoLite reduced the carbon footprint of the primary textile used by approximately 30 percent, while maintaining the performance and durability of the product.

- By removing the printing from the inside of each shoe box lid, Brooks Running reduced its shoe box printing costs by eight percent. By creating two additional shoe box sizes, allowing for a tighter fit around several core shoe sizes, the company saved 35,000 square meters of material.

- In 2010 The Wall Street Journal featured a graphic interactive example from a study conducted by Levis, analyzing the life cycle of a pair of jeans. For this single pair of jeans, the cotton comes from the Mississippi Delta, and the fabric is woven in North Carolina. Then it’s shipped to the Dominican Republic for cutting and then to Haiti for sewing and then back to the D.R. for “finishing.” Then the completed 501s are distributed all throughout the U.S. Oh, and they have buttons and metal grommets that were manufactured all over the world, too. How to calculate even the actual transportation costs?

Other Initiatives

The Eco Index isn’t the only initiative working to make production processes more transparent. According to the OIA, the index takes into account current existing standards from bluesign (see below) and other certification organizations, so as not to duplicate or confuse efforts.

- Bluesign is an independent industry textile standard company based in Switzerland, which also examines the production and life cycle of products using something they call an Input Management Process. Bluesign offers a certification for compliance with the bluesign criteria. For example, PrimaLoft recently had its One, Sport, and Eco insulations certified by bluesign. Bluesign member companies, like Patagonia, REI, and The North Face, use bluesign standards to manage environment and health and safety issues in their supply chain.

- GOTS is the Global Organic Textile Standard, a processing standard for textiles made from organic fibers worldwide.

- Oeko-Tex Standard 100 is an international testing and certification system limiting the use of certain chemicals in textiles.

- REACH is a European Union regulation on Registration, Evaluation, Authorisation and Restrictions of Chemicals in textile and leather products.

by Bobbi Maiers

by Bobbi Maiers